The PassiveLogic Hive™

Autonomous Control Platform.

One Box.

One Complete Solution.

Imagine taking an entire control panel and rolling everything into a single product that works in any jobsite. Then add in a touch screen to help you wire and a next-gen chipset to power autonomous control right at the edge. That’s the Hive Autonomous Platform.

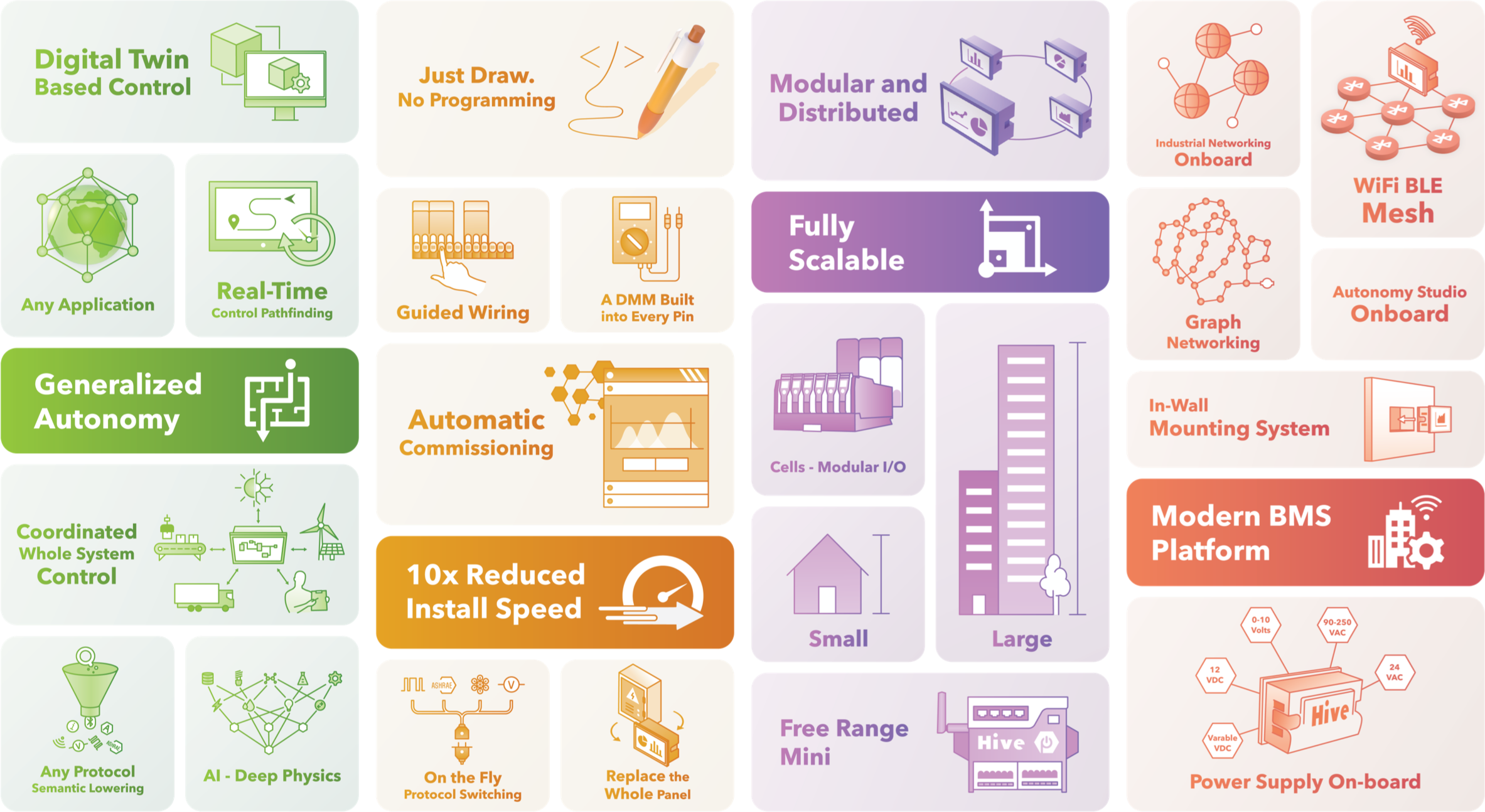

General Purpose Autonomy.

One Complete Solution.

Coordinated Whole-System Control.

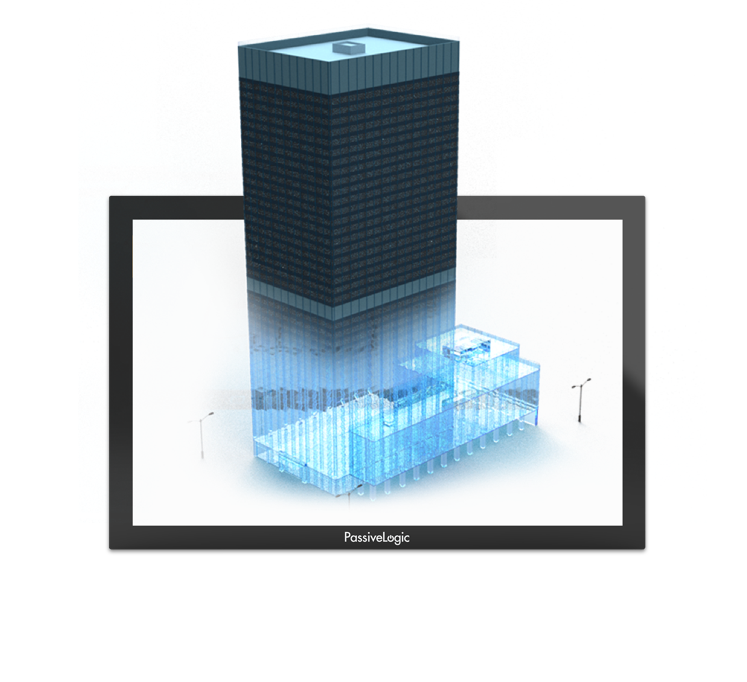

Powered by Quantum Digital Twins.

Quantum digital twins describe a building’s entire world: from the zones, to the weather, to the physics of the mechanical systems. The PassiveLogic Hive leverages this digital twin to enable synchronized control across systems that used to operate independently — unlocking big gains in operational efficiency.

Control Autopilot.

Seriously.

The Hive takes a Quantum digital twin and runs millions of simulations in just seconds to determine the optimal path of future control decisions for the coming hours to days. It then pushes fresh control sequences to equipment in real time. If conditions change, the process repeats automatically and new sequences are generated. Goodbye static/reactive thermostatics.

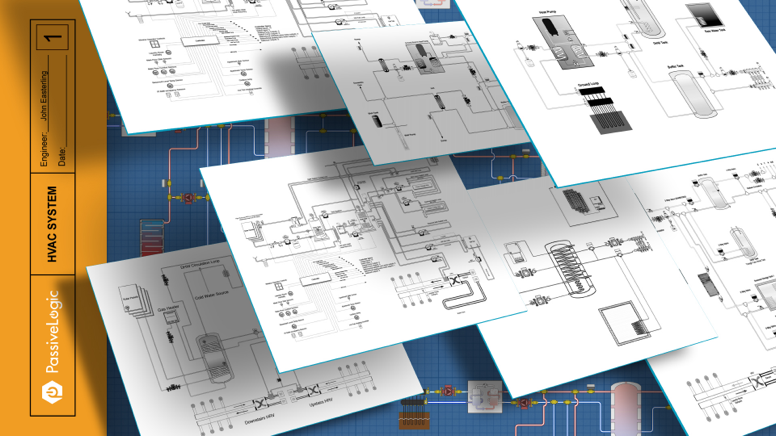

General Purpose Autonomy.

Define Any System.

PassiveLogic has crafted a modular software and hardware platform that allows you to take on just about any systems control project. Our initial focus is HVAC — every single building has these systems — but our solution is flexible to solve for the demands of anything else happening in your building.

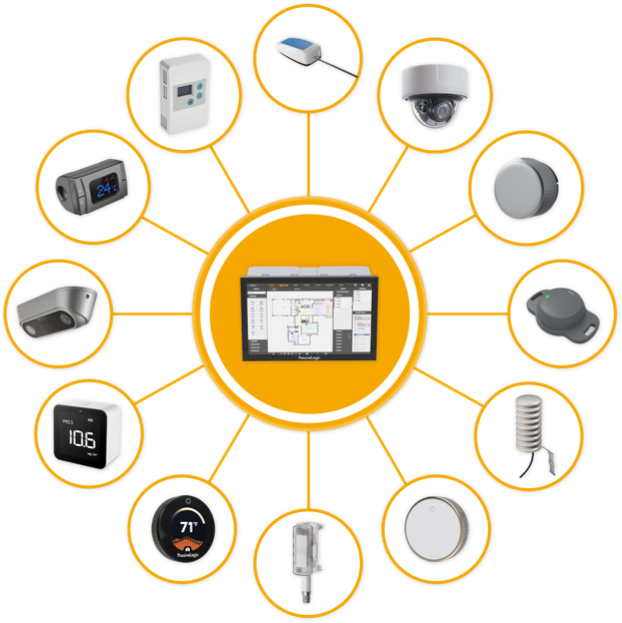

Communicate Many Protocols.

Play Well with Others.

The Hive utilizes Cell Modules with unique capabilities to be able to connect and communicate with thousands of different devices. And Quantum digital twins automatically handle the integration headache between different industry protocols. Plug and play finally comes to the built world.

Zero to Autonomous.

In Just 30 Minutes.

Replace the Whole Control Panel.

Install Anywhere.

We took most of the stuff that makes up a control panel — power supply, relay switches, logic controllers, to name a few — and stuffed it all into a single unit. And the Hive is designed to install into any standard-depth wall cavity, so you can save hours on panel construction and install the Hive anywhere you want.

On-Screen Guided Wiring.

Self-Commissioning.

The Hive has a touch screen built-in, enabling live guided wiring and automatic error detection during installation. If you have a wiring change in the field, just switch things up right on the device. When fully connected, Hive controllers can run through the commissioning process on their own, no specialist required.

Wired or Wireless.

Easy Retrofits.

The Hive controller readily installs into both new construction and retrofit projects. It can deploy as a purely PassiveLogic system, or work with existing controls in various retrofit scenarios. Go wireless with our secure Wi-Fi and enhanced wireless mesh to make retrofits even more of a breeze.

One Hive or One Hundred.

Fully Scalable Platform.

Coffee Shops to Skyscrapers.

Hives are Always Right.

The PassiveLogic Hive is a modular distributed work engine. This means it is the right tool no matter how big or small your project. Use one Hive to tackle a small job with less than 48 I/O. Or link a hundred together, and they will automatically aggregate their compute resources into a distributed supercomputer for coordinated control across even the biggest sites.

Network Your Way.

Chains, Loops, Wireless, etc.

Connect up your controls system in the way that actually makes the most sense for your project. Use the Hive’s 4 Ethernet switches to create any wired topology that you want — just wire it up and the Hives will figure out communication on their own. Or make it even simpler and go wireless on our own secure Wi-Fi network.

Built-in Redundancy.

Self-Networking Devices.

As a distributed compute system, PassiveLogic Hive networks are not dependent on any single device. If a Hive gets taken out of commission, the remaining controllers take over and find a way to re-route communications, if possible. And your building keeps going.

A Modern BMS Platform.

Turn Automation up to 11.

Freaking Powerful.

Distributed Supercomputing.

Every Hive controller contains a 12-core processor and an NVIDIA GPU on board. And networks of Hives combine their compute power to create a distributed supercomputer right in your building. Finally, building controls get the power they need to become fully autonomous.

Enhanced Security.

Autonomy at the Edge.

Hive controllers have everything they need to function on-site, no cloud connection required. Enable the level of security you need for your control network, from one-way synchronization all the way to a fully air-gapped system if needed.

Live Digital Twins.

Intelligent in Any Conditions.

Quantum digital twins live on every Hive device and update continuously any time the control system learns something new. This allows the Hive platform to predictively adapt to different conditions, and building managers always get the most up-to-date information on their systems.